Product parameters:

| Specific gravity: 2.1-2.3g/cm3 | Compression strength: 12Mpa | Breakdown voltage: 19Kv/mm |

| Tensile length: 13.72-34.3Mpa | Shore hardness: D50-55 | Influence of strong or weak acid, alkali and solvent: None |

| Elongation: 150-400% | Dynamic friction coefficient: 0.06 | Temperature: -190-260℃ |

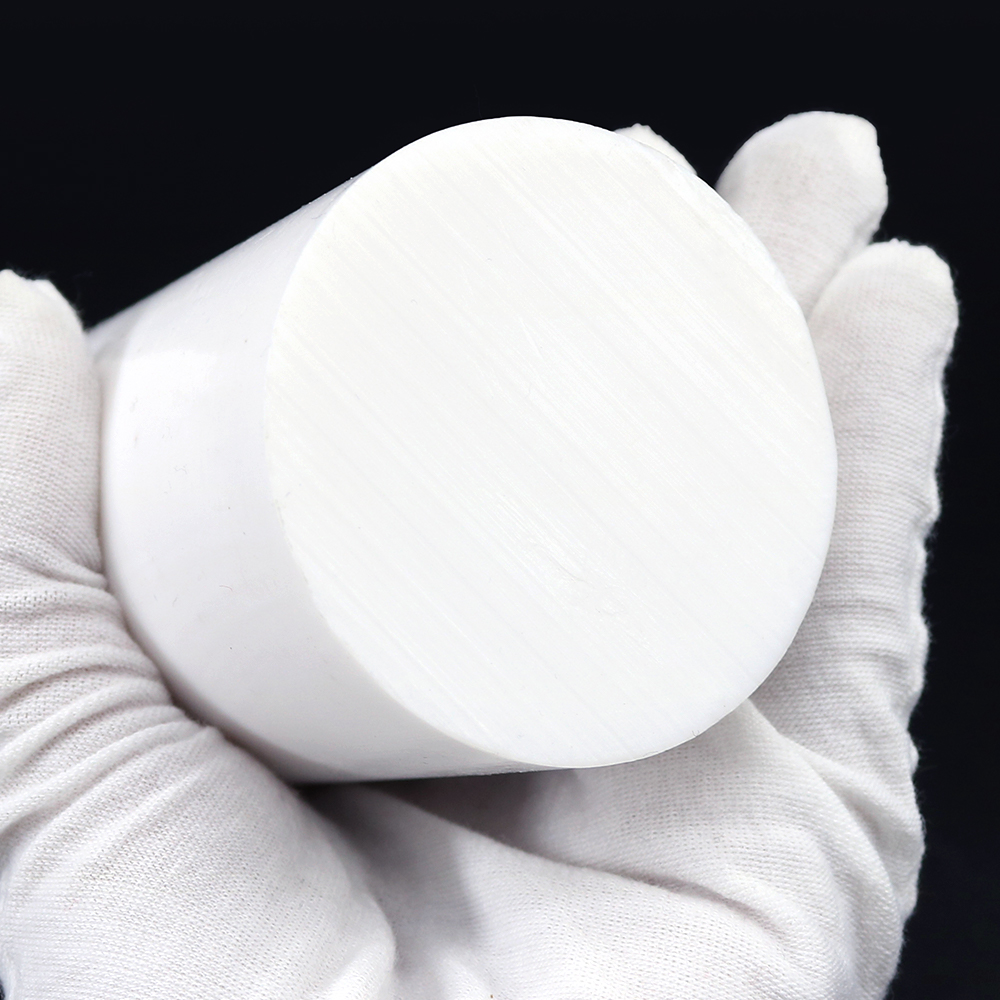

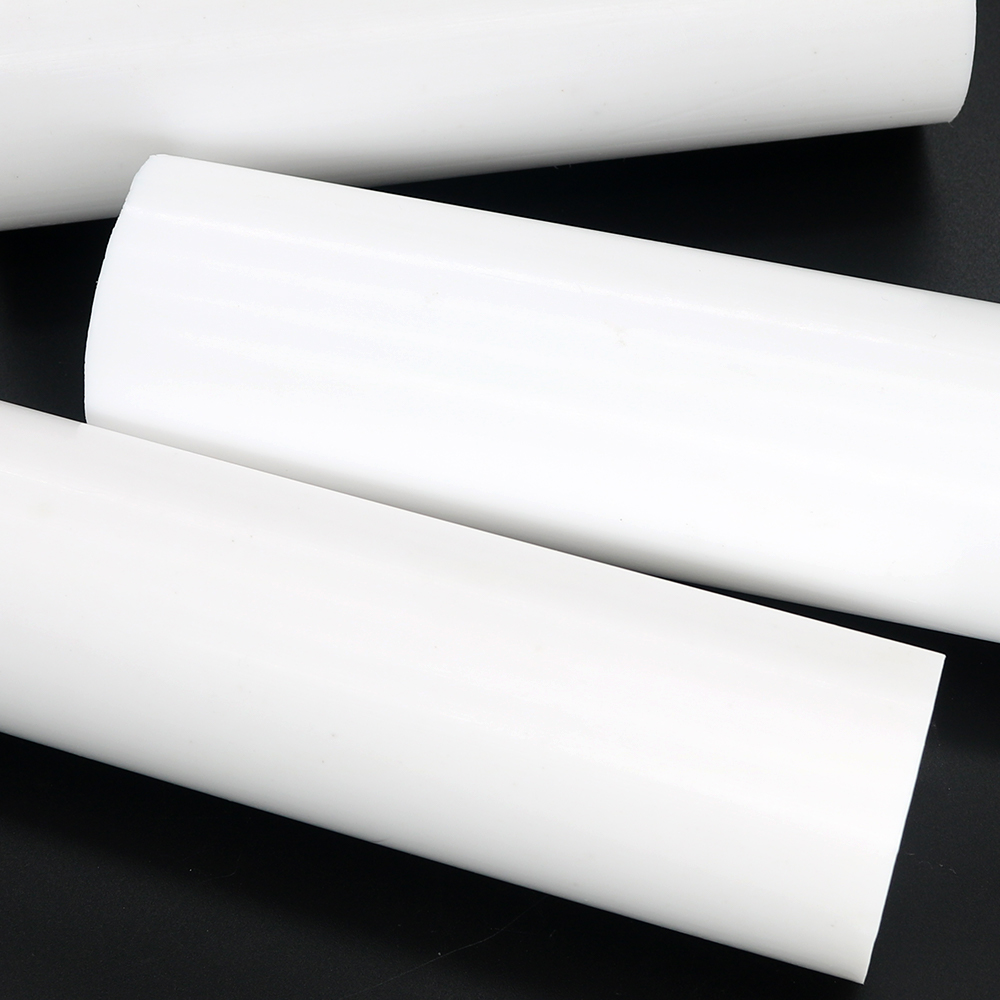

product description

Polytetrafluoroethylene (PTFE) rods, often referred to as the "King of Plastics", are commonly used in many industries due to their unique physical and chemical properties. The material is made through processes such as molding, paste extrusion or plunger extrusion, making it a rod with high mechanical properties and corrosion resistance.

1. Push rods and molded rods: PTFE rods are mainly divided into two types: push rods and molded rods. Push rods are produced by paste extrusion, while molded rods are manufactured by high-temperature compression molding technology. These two processes ensure the performance requirements of PTFE rods in different applications.2. Production process: The production of PTFE rods involves extruding and heating the pre-sintered PTFE powder raw materials at high temperatures, and then cooling and other processing steps to form the finished product. These steps ensure that the PTFE rods have good physical and chemical properties to meet the needs of specific industrial applications.Carefully select the type and size of PTFE rods based on operating temperature, chemical environment and mechanical requirements to achieve excellent performance.的性能表现。

Show details

Understand product knowledge

product advantages

1. New material, high temperature resistance, acid and alkali resistance, corrosion resistance

2. Wear resistance, high strength and friction resistance

3. Complete specifications, zero-cut processing, non-standard customization

Precautions

1. Correct installation and fixation

2. Control temperature and pressure

3. Regular inspection and replacement