1.Industrial field

Polytetrafluoroethylene is mainly used to make seals, insulation materials, anti-corrosion coatings, etc. Due to its high temperature and corrosion resistance, PTFE can work stably for a long time in high temperature and harsh environment, effectively preventing leakage and corrosion. At the same time, its low friction coefficient makes it an ideal lubricating material, which can reduce mechanical wear and friction loss.

2.Food industry

Polytetrafluoroethylene is mainly used in the manufacture of food processing equipment. Due to its high temperature resistance and corrosion resistance, PTFE can ensure the hygiene and safety of food processing. At the same time, its low friction coefficient makes food processing equipment more efficient and smooth. In addition, PTFE can also be used in the manufacture of food packaging materials, providing a good protection and storage environment for food.

3.Medical field

Polytetrafluoroethylene is widely used in the manufacture of medical devices. For example, it can be used as a coating material for medical devices such as artificial joints, heart valves, and blood vessels because of its excellent biocompatibility and anticoagulant properties. In addition, PTFE can also be used to manufacture medical dressings, surgical instruments, etc., providing safe and reliable solutions for the medical field.

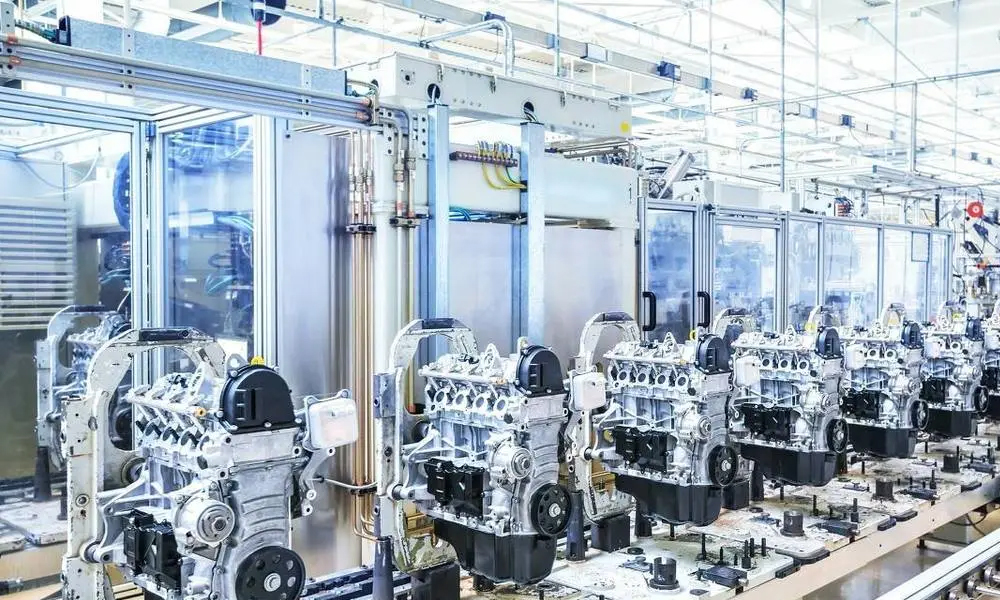

4.Automotive

PTFE products are often used in the automotive industry for high-temperature, high-performance sealing materials, such as brake master cylinder gaskets, oil filling port gaskets, piston rings, hydrogen fuel cell seals, electric turbine housings and bearings.